Industrial digitalization fundamentally transforms the heavy equipment sector, unlocking unprecedented opportunities and revolutionizing traditional practices. This shift is not just about integrating new technologies—it's about reimagining how machinery is designed, manufactured, and operated. In this detailed exploration, we delve into the transformative potential of digital technologies and their impact on efficiency, innovation, and the future trajectory of the heavy equipment industry. From IoT and robotics to advanced analytics, we uncover the benefits and challenges of embracing digitalization in a complex, fast-evolving domain.

The Heavy Equipment Industry: An Ecosystem of Opportunities

The heavy equipment industry forms the backbone of critical sectors like construction, agriculture, mining, and transportation. Beyond its role in infrastructure development, it also drives global economic growth, technological progress, and innovation. Here are some foundational insights into this dynamic industry:

- Broad Equipment Scope: Heavy equipment ranges from massive excavators and cranes to precision agricultural tools and cutting-edge industrial machinery. Each category addresses specific needs across diverse industries.

- Market Dynamics and Trends: The industry responds to global factors, including urbanization, infrastructure investment, and sustainability goals. Economic fluctuations and regulatory changes play significant roles in shaping demand.

- Innovation Imperatives: The push for efficiency, safety, and environmental stewardship has made R&D investment a cornerstone for leading manufacturers.

- Globalized Operations: Supply chains for heavy equipment are global, involving intricate networks of suppliers, distributors, and service providers.

- Sustainability as a Competitive Edge: The industry’s shift toward energy-efficient and environmentally friendly technologies has introduced a new dimension to competition and market leadership.

These elements collectively highlight the industry’s scope, challenges, and opportunities, setting the stage for digital transformation.

How Digitalization Revolutionizes Heavy Equipment Manufacturing

Industrial digitalization is more than a trend; it is necessary for organizations aiming to remain competitive. Below are some critical areas where digitalization delivers transformative benefits:

Advanced Production Planning and Resource Optimization

Digital platforms powered by AI enable real-time production planning. These systems integrate demand forecasting with resource allocation, minimizing waste and ensuring efficient material use. For example, predictive analytics in supply chain management can reduce inventory holding costs while ensuring timely delivery.

Automation and Robotics

Robotic systems are revolutionizing assembly lines by performing repetitive tasks with unmatched precision. Collaborative robots, or "cobots," are particularly effective in integrating human intelligence with machine efficiency. This synergy improves productivity and ensures consistent quality standards.

Predictive Maintenance and Operational Continuity

Sensor-enabled equipment continuously monitors performance, detecting anomalies before they lead to failures. For instance, manufacturers using IoT-driven predictive maintenance report significant reductions in unplanned downtime, translating into higher productivity and lower maintenance costs.

Supply Chain Resilience and Visibility

Digital supply chain solutions leverage blockchain and advanced analytics to enhance transparency and traceability. Smart contracts and real-time tracking reduce inefficiencies and strengthen collaboration across the supply chain.

Remote Monitoring and IoT Integration

IoT connectivity allows manufacturers to monitor equipment performance remotely. This capability minimizes the need for onsite inspections and facilitates faster issue resolution, reducing operational delays.

Enhanced Decision-Making Through Big Data

Data collected throughout the equipment lifecycle—design, production, and usage—can be analyzed for actionable insights. Manufacturers can optimize processes, improve product design, and deliver tailored solutions that meet specific customer requirements.

Emerging Trends Shaping Digitalization in Heavy Equipment

As digital transformation gains momentum, several trends are emerging as key drivers of innovation:

- IoT for Operational Excellence: Equipment embedded with IoT sensors enables real-time monitoring, maintenance, and optimization, creating a seamless operational ecosystem.

- AI and Machine Learning for Process Improvement: AI algorithms analyze vast datasets to enhance production efficiency and improve predictive capabilities.

- Digital Twins for Predictive Modeling: Virtual replicas allow manufacturers to simulate performance, identify potential failures, and optimize equipment reliability.

- Augmented and Virtual Reality for Training: AR and VR technologies revolutionize workforce training and remote troubleshooting, enabling faster upskilling and operational efficiency.

- Sustainability Through Smart Manufacturing: Digitalization supports sustainable manufacturing practices from energy-efficient designs to recycling initiatives.

- Cloud and Edge Computing for Scalability: Cloud platforms provide centralized data access, while edge computing enables faster decision-making closer to equipment locations.

Case Studies: Pioneering Digital Success in the Heavy Equipment Sector

Leading companies are already reaping the rewards of digital transformation:

|

Technology

|

Company

|

Leading companies are already reaping the rewards of digital transformation:

|

|---|---|---|

|

Internet of Things (IoT)

|

Komatsu

|

Reduced downtime through predictive maintenance

|

|

Augmented Reality (AR)

|

CNH Industrial

|

Enhanced efficiency in operator training

|

|

Digital Twins

|

Siemens

|

Improved reliability via virtual testing

|

|

Robotics and Automation

|

ABB

|

Increased precision in manufacturing

|

|

Blockchain

|

Volvo Construction Equipment

|

Transparent and efficient supply chain management

|

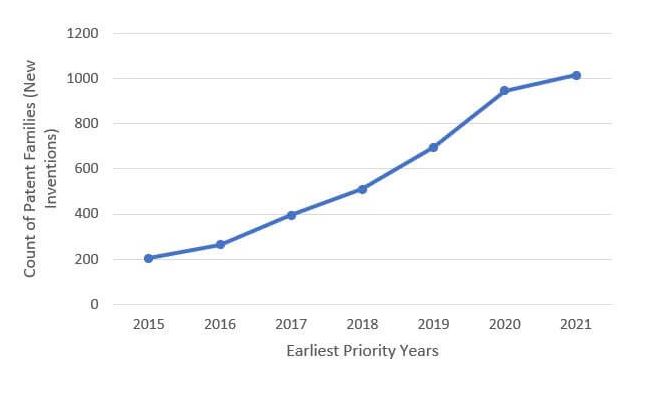

To gauge the breadth of innovation within fields such as construction, drilling, and mining, a quick search through a patent database reveals the following trends on industrial digitalization:

Figure 1: This chart was generated by the Evalueserve IPRD team following a high-level patent database search.

The sharp rise in new inventions over recent years highlights the emphasis on digital adaptation.

Note: The chart is based on a preliminary search. A more detailed search could reveal even higher figures.

These use cases underscore the versatility and value of digital technologies in addressing industry challenges.

Challenges to Overcome in Industrial Digitalization

Despite its numerous benefits, industrial digitalization presents significant challenges that manufacturers must address:

- High Upfront Costs: Adopting digital technologies requires significant equipment, software, and training investment.

- Data Security Concerns: Protecting sensitive operational data from cybersecurity threats is a growing priority.

- Integration of Legacy Systems: Retrofitting older machinery to align with modern systems often demands extensive effort.

- Workforce Training Needs: Equipping employees with digital skills is essential to maximize the potential of new technologies.

- Complexity in Data Management: Extracting actionable insights from diverse data sources requires advanced analytics capabilities.

- Scalability: Ensuring digital solutions can grow with organizational needs is a long-term challenge.

Addressing these obstacles requires strategic planning, robust investments, and a commitment to continuous improvement.

Supporting Clients in Navigating Digital Transformation

At Evalueserve IP and R&D, we empower clients to leverage digitalization effectively:

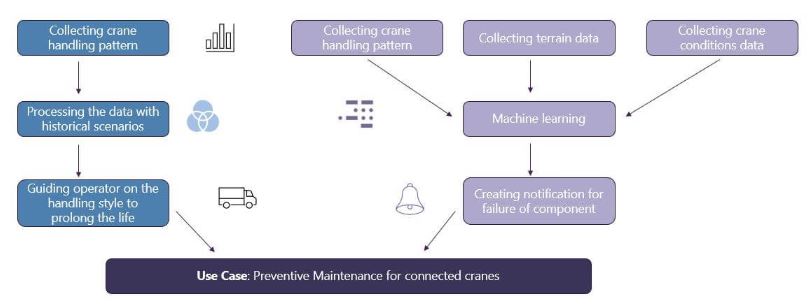

- Use Case Development: For a crane manufacturer, we identified high-impact digital solutions tailored to their operations.

- Partner Benchmarking: We assist clients in evaluating technology partners based on relevance, readiness, and financial stability.

Conclusion: The Path Forward for the Heavy Equipment Industry

Digitalization is not merely a tool for operational improvement—it is a catalyst for redefining the heavy equipment industry. By embracing IoT, AI, and other transformative technologies, manufacturers can unlock unparalleled efficiency, foster innovation, and address emerging challenges head-on. As the industry continues to evolve, companies prioritizing digital transformation will shape a more sustainable, efficient, and innovative future.

The time to act is now. For heavy equipment manufacturers, digitalization offers a blueprint for growth and resilience in a rapidly changing world.

Talk to One of Our Experts

Get in touch today to find out about how Evalueserve can help you improve your processes, making you better, faster and more efficient.