As the industrial revolution continues (Read: Industry 4.0: Revolutionizing Manufacturing with Smart Technologies) and connectivity solutions evolve from 5G to 6G (Read: 6G: Supercharging the Future of Digital Manufacturing), the Oil and Gas industry is undergoing a renaissance driven by a surge of innovation.

Oil & Gas 4.0, or the Digital Oilfield, is transforming operations with cutting-edge technologies like Artificial Intelligence (AI), the Internet of Things (IoT), Augmented Reality (AR), Cloud Computing, and more. This paradigm shift from traditional methods to new technologies is also fueled by Data Analytics, Efficiency, Sustainability (aligned with ESG), Scalability, and Agility.

The traditional oil and gas landscape faces significant challenges, including fluctuating energy prices, environmental concerns, and the need for operational excellence. However, digital transformation offers robust solutions to these issues, potentially reshaping the industry and ushering in a new era of possibilities.

The Drivers of Change

At Evalueserve IP and R&D, we’re not just observing this revolution but actively guiding our customers to lead in their digital transformation journeys. In an industry characterized by volatility and environmental pressures, our expertise in digitalization emerges as a game-changer, providing:

- Enhanced Exploration & Production: Advanced data analytics applied to seismic data leads to more accurate reserve identification and optimized drilling strategies.

- Streamlined Operations: IoT sensors and real-time data monitoring empower companies to optimize production processes, minimize downtime, and predict equipment failures.

- Improved Safety & Environmental Performance: Digital solutions like AI and remote monitoring are not just tools but game-changers. They contribute significantly to a safer work environment and enable proactive leak detection, demonstrating the industry’s commitment to reducing environmental impact.

- Data-Driven Decision Making: Big Data analytics empower companies to make informed decisions based on real-time insights, maximizing efficiency and profitability.

These challenges, combined with the rapidly growing market for digital oilfield solutions, create a compelling need for companies to embrace digital transformation. According to a report from MarketsAndMarkets, the Global Digital Oilfield Market was valued at $30 billion in 2023 and is expected to reach $43 billion by 2029. This significant growth highlights the increasing investment in digital transformation across the Oil & Gas industry.

Sustainability and Digital Transformation

Digital transformation in oil & gas is not just about efficiency and profit; it’s intrinsically linked to sustainability goals. By leveraging cutting-edge technologies, companies can significantly reduce their environmental impact and promote sustainability through several initiatives.

Some companies implementing these technologies have the potential to contribute towards sustainable development:

- Equinor: This company’s AIM (Artificial Intelligence Maturation) project utilizes AI to automate healthy path generation and suggest optimal drilling solutions, reducing the number of wells needed and lowering the overall carbon footprint.

- Shell: Shell is applying deep learning to analyze seismic data for oil exploration, allowing for fewer seismic surveys and minimizing the environmental impact of traditional exploration methods.

- Saudi Aramco: Saudi Aramco launched a powerful AI tool called Aramco Metabrain AI. Trained on massive amounts of company data, this AI can analyze drilling plans and recommend optimal healthy options, potentially reducing drilling footprint and energy use. It can also predict market trends for refined products, helping Aramco optimize downstream operations. While currently focused on drilling, this powerful AI could be harnessed for applications like optimizing CCUS processes, further solidifying its role in a more sustainable oil & gas industry.

Understanding the Oil & Gas Value Chain

A comprehensive grasp of the oil & gas value chain is crucial for effective digital transformation strategies. As recognized by the World Economic Forum, a compelling illustration of how digital solutions have transformed the oil and gas sector is Saudi Aramco’s Uthmaniyah Gas Plant – The Lighthouse Manufacturing Facility. One of the world’s largest gas processing plants, it uses advanced analytics and AI solutions to increase productivity while enhancing its operating facilities’ safety, reliability, and efficiency. Using drones and wearable technologies to inspect pipelines and machinery has helped cut inspection time by 90%.

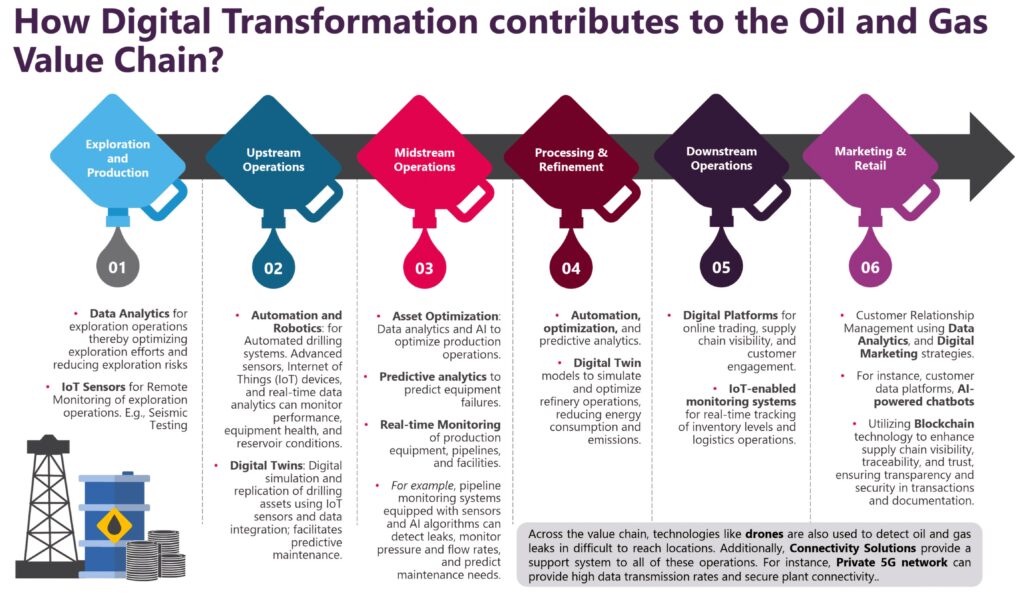

To understand the segmentation of the value chain and its dependence on technologies, here’s a breakdown of the key segments and the impact these technologies are creating on each:

Exploration & Production

- Data Analytics for Exploration: Advanced analytics interpret seismic data, identify promising drilling locations, and optimize exploration efforts, reducing risks and costs. For example, Shell uses deep learning to analyze seismic data for oil exploration, powered by NVIDIA’s DGX and AI.

- IoT Sensors for Remote Monitoring: Sensor networks deployed during seismic testing and exploration activities transmit real-time data for remote monitoring, improving safety and operational efficiency. For example, in 2021, Hiber signed a deal with Shell to roll out remote IoT monitoring of wells using HiberHilo.

Upstream Operations

- Automation and Robotics: Automated drilling systems with advanced sensors, IoT devices, and real-time data analytics can monitor performance, equipment health, and reservoir conditions, allowing for proactive maintenance and improved healthy productivity. For example, Equinor’s AIM project uses AI to auto-generate healthy paths and suggest optimal drilling solutions.

- Digital Twins: Digital simulations of drilling assets, created using data from IoT sensors, enable predictive maintenance by identifying potential equipment failures before they occur. For example, Yokogawa’s KBC Co-Pilot Program® creates high-fidelity digital twins for real-time performance improvement.

Midstream Operations

- Asset Optimization: Data analytics and AI optimize production processes across pipelines, storage facilities, and transportation networks, maximizing throughput and minimizing energy consumption.

- Predictive Analytics: Advanced algorithms analyze sensor data to predict equipment failures in pipelines and other infrastructure, allowing for preventive maintenance and avoiding costly downtime. For example, ADNOC and SLB’s AR360 platform uses AI to optimize field development plans.

- Real-time Monitoring: AI-powered pipeline monitoring systems with sensor technology continuously track pressure, flow rates, and other parameters to detect leaks, optimize transportation, and predict maintenance needs. For example, ARAMCO’s Uthmaniyah Gas Plant uses drones for pipeline inspection.

Processing & Refinement

- Automation, Optimization, and Predictive Analytics: Refinery operations are increasingly automated, with data analytics and AI used to optimize process parameters, minimize waste, and reduce energy consumption.

- Digital Twin Models: Digital simulations of refineries are used to model and optimize production processes before implementation, leading to improved efficiency and reduced emissions. For example, Yokogawa’s KBC Co-Pilot Program® creates high-fidelity digital twins for real-time performance improvement.

Downstream Operations

- Digital Platforms for Operations: Digital platforms facilitate online trading, enhance supply chain visibility, and improve customer engagement. These platforms may include features like order management, logistics tracking, and real-time inventory data.

- IoT-enabled Monitoring Systems: IoT-enabled monitoring systems enable real-time tracking of inventory levels and logistics operations, allowing for optimized product distribution and improved customer service.

Marketing & Retail

- Customer Relationship Management (CRM): Data analytics and digital marketing strategies are used to personalize customer experiences and build stronger relationships. This may involve customer data platforms, AI-powered chatbots, and targeted marketing campaigns.

- Blockchain Technology: Blockchain technology enhances supply chain visibility, traceability, and trust by providing a secure and transparent record of transactions and documentation. This can improve customer confidence and brand reputation. For example, ADNOC and Siemens Energy’s pilot program uses blockchain to track CO2 emissions in low-carbon energy certificates.

The infographic below shows how the digitalization at each segment fuels the value chain:

Other disruptive technologies and innovations are also essential in the digital transformation journey. One example is ARAMCO’s Shallow Water Inspection and Monitoring Robot (SWIM-R), a versatile robot designed to inspect pipelines in shallow water environments. Evalueserve has continuously assisted its customers in tracking these disruptive technologies and staying ahead in innovation and transformation.

The DISRUPT Framework

Evalueserve’s DISRUPT Framework can help you navigate the digital transformation seamlessly. It consists of a step-by-step analysis of each part of the oil and gas value chain with action-oriented insights for customers. The DISRUPT Framework is broadly divided as follows:

- Design: Our experts craft a roadmap for specific technologies, analyzing their growth potential and impact on your operations to ensure alignment with your sustainability goals.

- Identify: Our experts delve into research, patents, and industry reports to pinpoint novel applications and growth areas for relevant technologies.

- Summarize: We provide clear, concise reports highlighting key developments and insights to guide your decision-making.

- Reassess & Update: We continuously monitor the evolving technological and innovation landscape, periodically reassessing your chosen technologies and updating the report with new findings.

- Prioritize: We translate insights into actionable strategies, aligning your focus with your business’s most impactful opportunities.

- Technologize: We help you integrate these cutting-edge technologies into your existing infrastructure, identifying the features most relevant to your specific needs.

The Future Beckons

The future of oil and gas is inextricably linked to its digital transformation journey. As technologies like artificial intelligence (AI) and automation mature, we can expect a cascade of advancements that reshape the industry:

- Supercharged Automation: Mundane tasks will be seamlessly automated, freeing human expertise for strategic analysis, innovation, and problem-solving.

- Predictive, Proactive Maintenance: Real-time data analysis will evolve into a predictive powerhouse, anticipating equipment failures before they occur. This will minimize costly downtime and optimize maintenance schedules.

- Safety Redefined: Remote monitoring and AI-powered systems will create a quantum leap in safety standards. Workers will face fewer risks, and operations will benefit from increased stability.

- Sustainability as a Cornerstone: Digital solutions will significantly empower companies to reduce their environmental footprint. Imagine optimizing processes, minimizing waste, and promoting environmentally friendly practices – all fueled by digital innovation.

The Next Horizon: Industry 5.0 and Beyond

Oil and gas digital transformation extends beyond the current Oil & Gas 4.0 paradigm. The future beckons with Industry 5.0, a collaborative future where technology and human ingenuity work perfectly. While still evolving, Industry 5.0 promises a revolutionary leap for the digital oilfield:

- Human-Machine Symbiosis: Imagine a future where humans and machines collaborate seamlessly. AI and automation will augment human expertise, enabling personnel to solve complex challenges, make data-driven decisions, and unlock new levels of innovation.

- Sustainability as a Guiding Principle: Environmental responsibility will be paramount. Digital solutions will empower companies to minimize their environmental footprint, optimize resource utilization, and promote environmentally friendly practices throughout the value chain. Here, we might see advancements in areas like carbon capture, utilization, and storage (CCUS) technologies or the development of bio-based feedstocks for specific applications.

- Focus on Customization and Personalization: Industry 5.0 might shift towards customization and personalization within the oil & gas sector. This could involve tailoring production processes or products to meet specific customer needs or regional requirements.

Embrace the Change, Secure Your Future

The digital transformation of the oil and gas industry is well underway. By partnering with Evalueserve IP and R&D innovation services, you can leverage cutting-edge technologies to optimize operations, enhance efficiency, and ensure your company thrives in the evolving Oil & Gas 4.0 landscape.

Talk to One of Our Experts

Get in touch today to find out about how Evalueserve can help you improve your processes, making you better, faster and more efficient.