Why Sustainability Is Now Strategic

Pharmaceutical innovation has revolutionized global health, but its environmental footprint has remained under the radar compared to sectors like automotive or consumer goods. That is changing fast. Tightening climate commitments, investor scrutiny, and new disclosure mandates mean sustainability is no longer optional—it’s a competitive differentiator.

Did you know?

The pharmaceutical sector emits 55% more greenhouse gases per dollar of revenue than the automotive industry, producing an estimated 52 megatons of CO₂e in 2015, according to McMaster University analysis. Beyond carbon, pharmaceutical residues in wastewater persist in ecosystems, fueling antimicrobial resistance and biodiversity loss.

Where Are the Biggest Emission Hotspots?

While packaging and logistics matter, the real carbon epicenter lies upstream—in API synthesis and intermediate production. According to the McKinsey Study:

- API synthesis: Up to 80% of a medicine’s cradle-to-gate GHG footprint.

- Solvent-intensive batch processes: Account for 50–60% of PMI.

- Globalized chemical supply chains: Drive Scope 3 emissions.

Why API Manufacturing Is a Carbon Hotspot

API production is chemically intensive and highly carbon-emitting because it involves:

- Multi-step syntheses with high energy requirements.

- Large volumes of fossil-derived solvents.

- Hazardous waste from reactive intermediates.

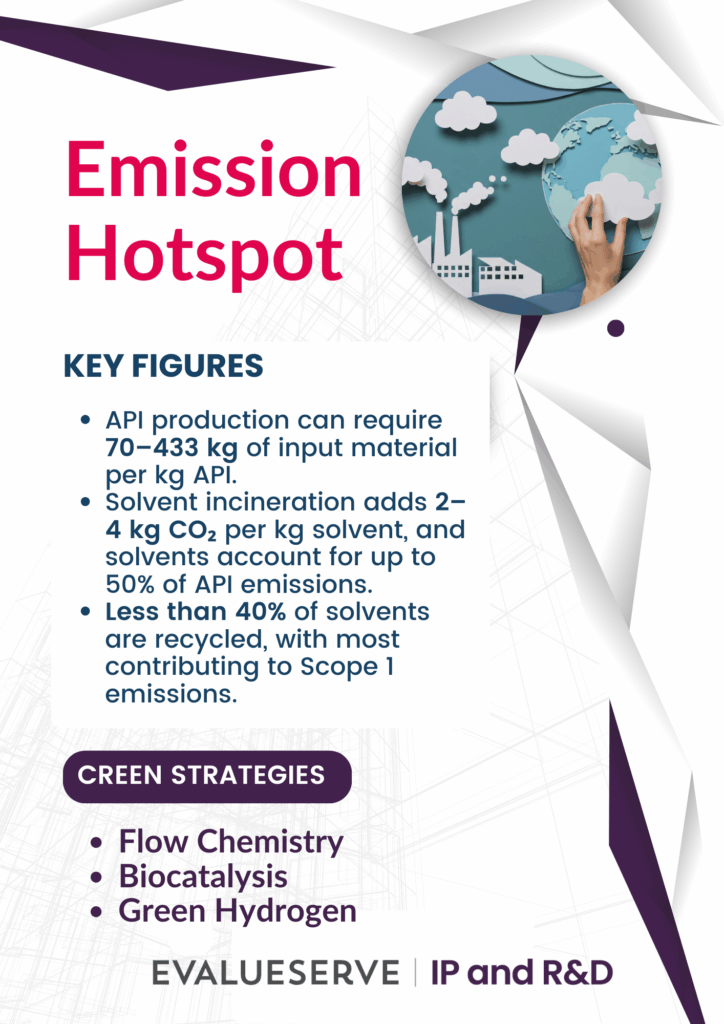

Key figures:

- API production can require 70–433 kg of input material per kg API.

- Solvent incineration adds 2–4 kg CO₂ per kg solvent, and solvents account for up to 50% of API emissions.

- Less than 40% of solvents are recycled, with most contributing to Scope 1 emissions.

Strategic Levers for Impact

1. Green API & Intermediate Synthesis

- Flow Chemistry: Improves heat/mass transfer and scalability; Asymchem reports 70% solvent reduction using continuous hydrogenation reactors.

- Biocatalysis: Enzyme-driven reactions under ambient conditions replace toxic transformations.

- Bio-based Intermediates: Fermentation-derived building blocks reduce reliance on fossil fuels.

- Green Hydrogen: Emerging as a replacement for fossil-based reducing agents.

Impact potential:

Retrofitting existing facilities with green chemistry and solvent recovery can cut emissions by 15–30%, while new greenfield plants with continuous manufacturing and renewable energy can achieve >50% reductions. You could explore more here: API manufacturing: The cost of decarbonization | McKinsey

2. Eco-Design: Sustainability Starts at Product Design

Eco-design integrates environmental considerations from the earliest stages of development. Principles include:

- Use low-impact materials (bio-based, recyclable).

- Design for energy efficiency (ambient conditions).

- Select APIs with fewer synthetic steps.

- Avoid persistent chemicals (e.g., PFAS).

- Improve molecular stability to reduce cold-chain requirements.

- Incorporate biodegradable excipients and modular delivery systems.

Case Study: Sanofi’s Eco-Design Strategy

Sanofi aims to apply eco-design to 100% of new products by 2025 and its top 20 best-sellers by 2030. Key achievements:

- Prevented 48,097 tons of solvent use through on-site regeneration (56% of total solvent use).

- Adopted catalytic and biocatalytic pathways to reduce PMI.

- Redesigned insulin synthesis using biocatalysis, boosting yield by 50%, saving 22 tons of raw materials and 61 tons of CO₂e per batch.

Sanofi’s approach shows sustainability is not just packaging—it’s embedded in R&D, route selection, and industrial scale-up.

3. Life Cycle Assessment (LCA)

LCA identifies environmental hotspots across raw material extraction, manufacturing, and end-of-life. It enables data-driven decisions for greener processes and procurement.

Why This Matters for Competitive Advantage

- Regulatory readiness: EU CSRD and US SEC mandates demand transparent climate disclosures.

- Investor confidence: ESG performance influences capital allocation.

- Procurement leverage: Sustainability-conscious buyers favor low-carbon suppliers.

- Cost savings: Reduced solvent use and energy efficiency lower operational costs.

Life Cycle Assessment: The Backbone of Data-Driven Sustainability

Life Cycle Assessment (LCA) evaluates environmental impacts from cradle to grave, offering clarity on material, energy, water, and waste flows across a product’s lifecycle. It helps pharma identify true hotspots and prioritise interventions.

Key LCA Applications in Pharma

- API production: Synthesis, energy use, solvents, and waste—up to 80% of a drug’s carbon footprint.

- Packaging & delivery systems: Compares recyclable, biodegradable, and refillable options.

- Formulation technologies: Identify greener alternatives to energy-intensive manufacturing.

Impact spotlight:

Greener synthesis routes identified through LCA can reduce GHG emissions by 40%+ while improving water and toxicity indicators. You could explore more here.

Digital Tools for Real-Time Insights

Platforms like OpenLCA, SimaPro, GaBi/Sphera, paired with databases like Ecoinvent, offer:

- Visualisation of carbon and water hotspots

- Scenario modelling for alternative materials and processes

- Cost–impact analysis

- Dashboard-driven decision support

With these tools, LCA becomes not just a reporting tool but an operational enabler.

4. Regulatory Momentum: Why Sustainability Is Becoming Mandatory

Global sustainability frameworks increasingly require transparent, quantified environmental data. Key regulations include:

- CSRD (EU)

- Product Environmental Footprint (PEF)

- EPA Safer Choice

- GHG Protocol & Scope 3

- SBTi

- ISO 14040/14044

Case Study: Europe’s Shift Toward Circular Design

EU frameworks are linking compliance, design, and lifecycle transparency:

- Ecodesign for Sustainable Products Regulation (ESPR): Expands durability, recyclability, and resource-efficiency criteria to most products.

- Digital Product Passport (DPP): Introduces traceable, verifiable environmental data for each product.

- PEF & ESRS (via CSRD): Harmonised metrics for climate, water, circularity, and pollution.

Life Cycle Inventory (LCI)—aligned with ISO standards—provides the quantitative backbone, enabling actionable sustainability decisions across design, sourcing, and manufacturing.

As highlighted in Evalueserve’s 2025 IP & R&D white paper, the convergence of Eco-Design, PEF, and LCA signals a pivotal shift: Sustainability is evolving from compliance to a core design principle.

How Evalueserve IP and R&D Helps

We support pharmaceutical and life sciences clients in:

- Quantifying emissions via cradle-to-gate LCA.

- Embedding eco-design principles in R&D.

- Engaging suppliers for Scope 3 reductions.

- Navigating regulatory intelligence for global compliance.

To see how sustainability can become a practical enabler of more innovative R&D and stronger product strategies, I invite you to explore our Environmental & Sustainability Services.

Talk to One of Our Experts

Ready to turn sustainability into a competitive edge?

Explore how Evalueserve turns green chemistry and LCA insights into real operational advantage.